In South Asia, the “oil to electricity” change of containerized frontal crane in port terminals is setting off a green revolution.

In South Asia, the “oil to electricity” change of containerized frontal crane in port terminals is setting off a green revolution.

Project address: a port in India

Project name: pure electric front crane modification scheme

Application scenario: Port and wharf

Our solutions:

After thoroughly understanding their needs, the PUMBAA R & D team conducted a frontal lifting feasibility analysis, and controlled the feasibility of the project from the aspects of technology, quality, safety, benefit and so on;

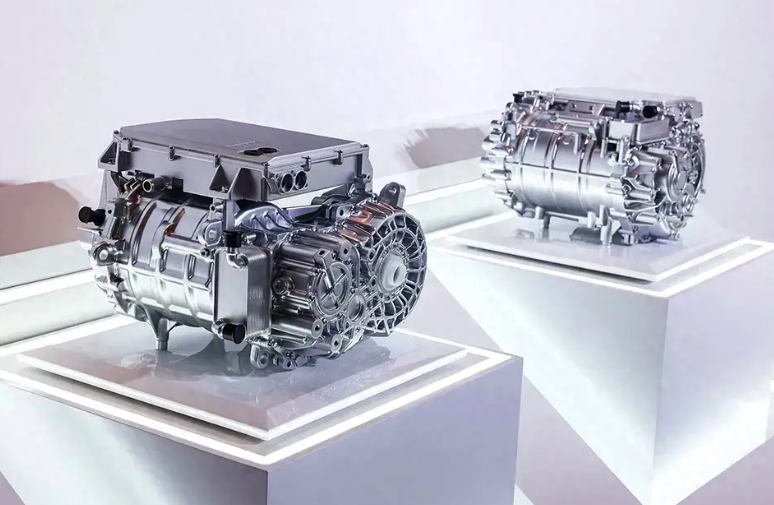

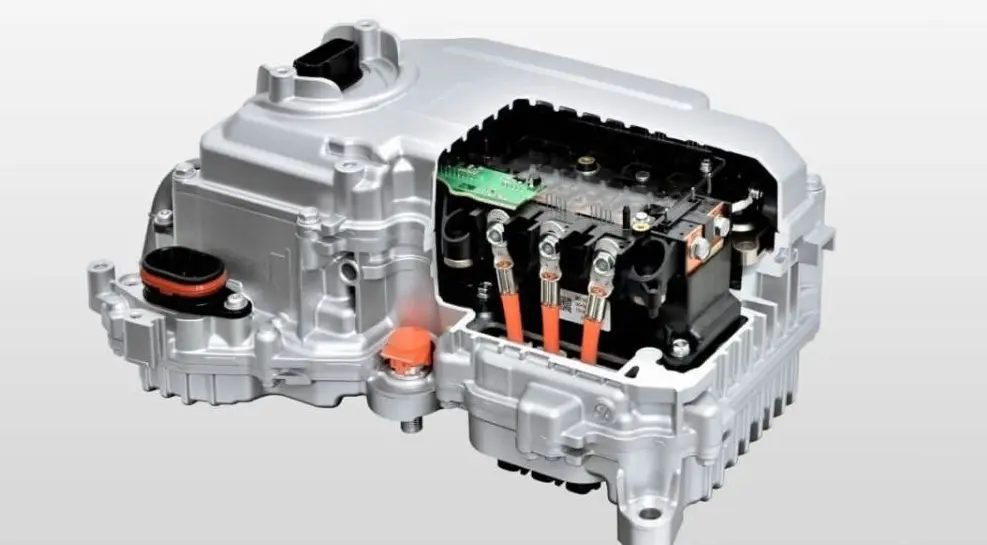

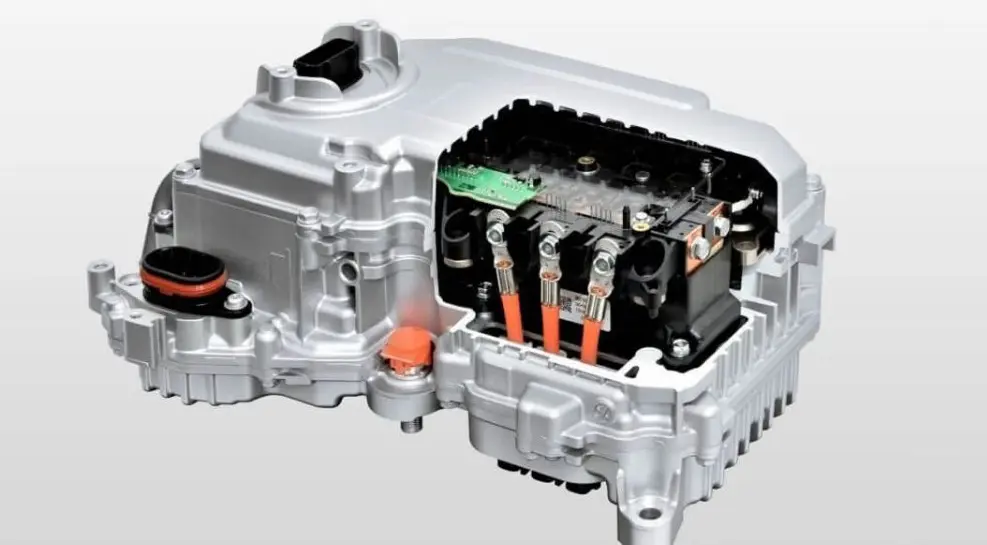

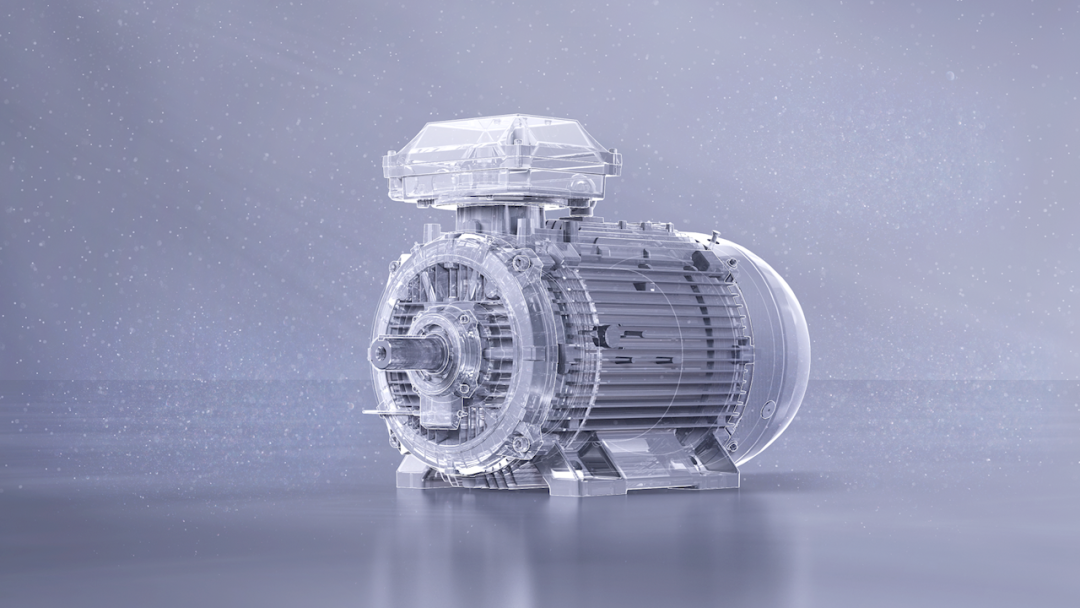

A comprehensive solution was then presented, which included the motor and motor controllers. This combination ensures that our solutions fully meet the unique needs of their EV projects.

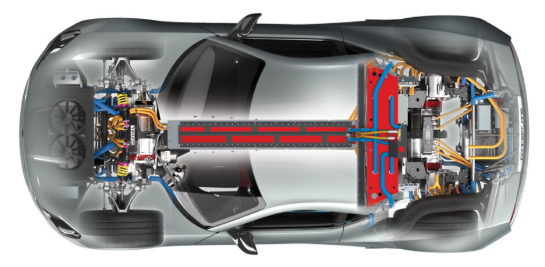

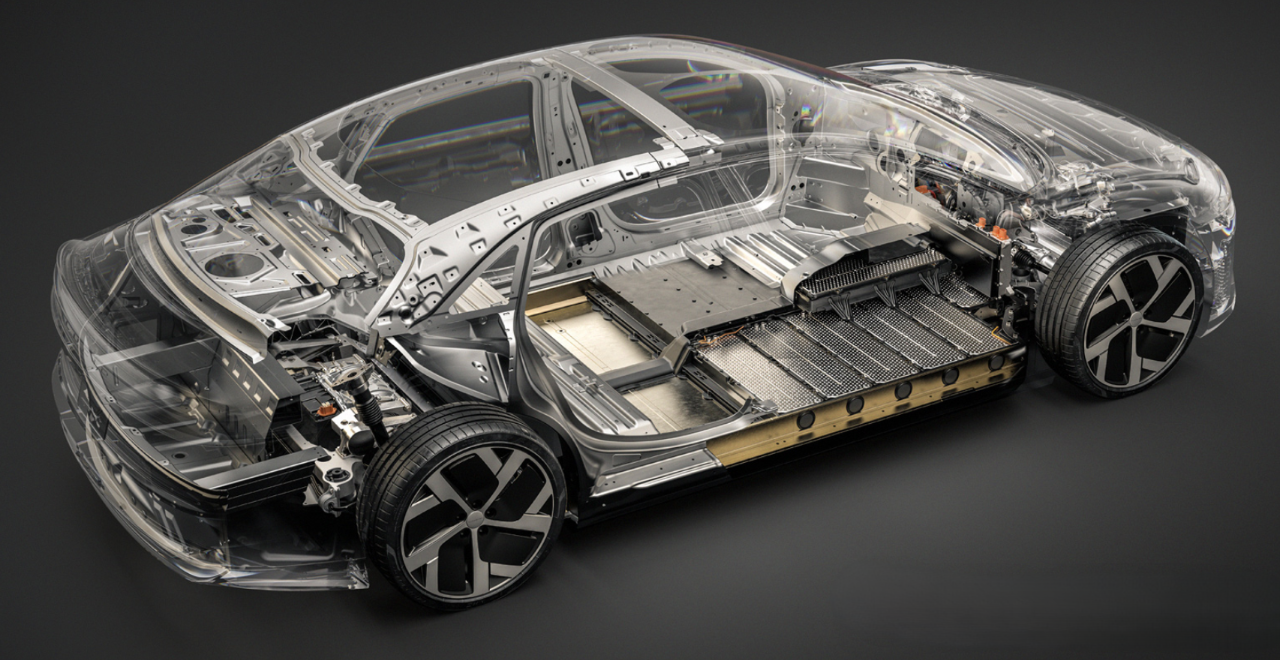

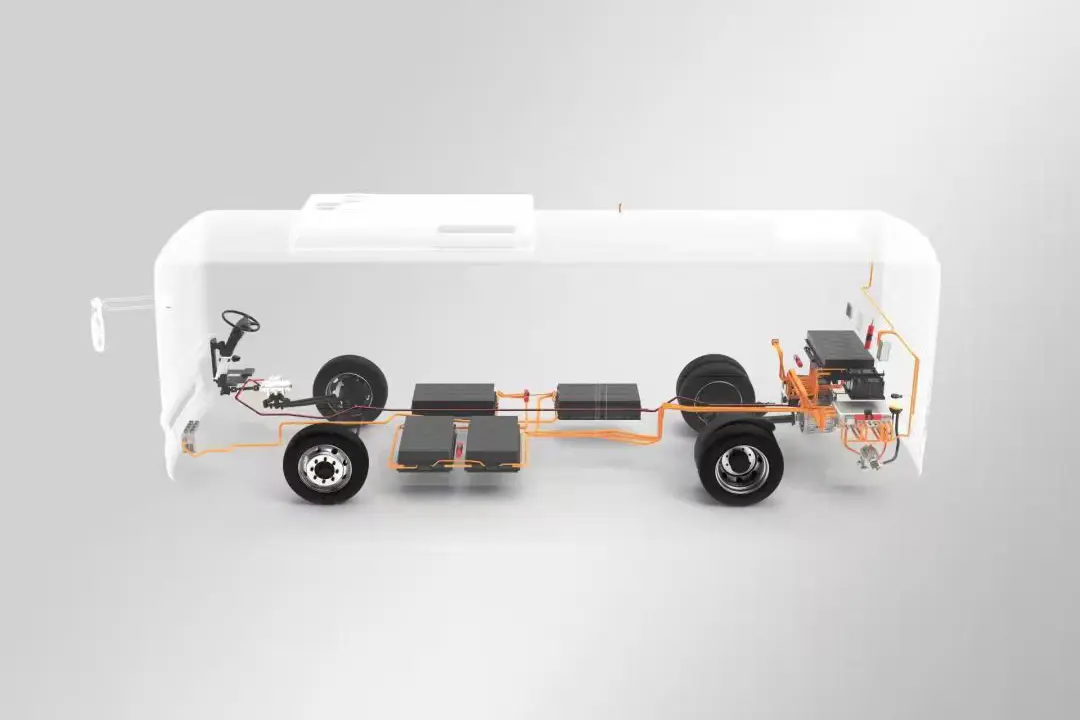

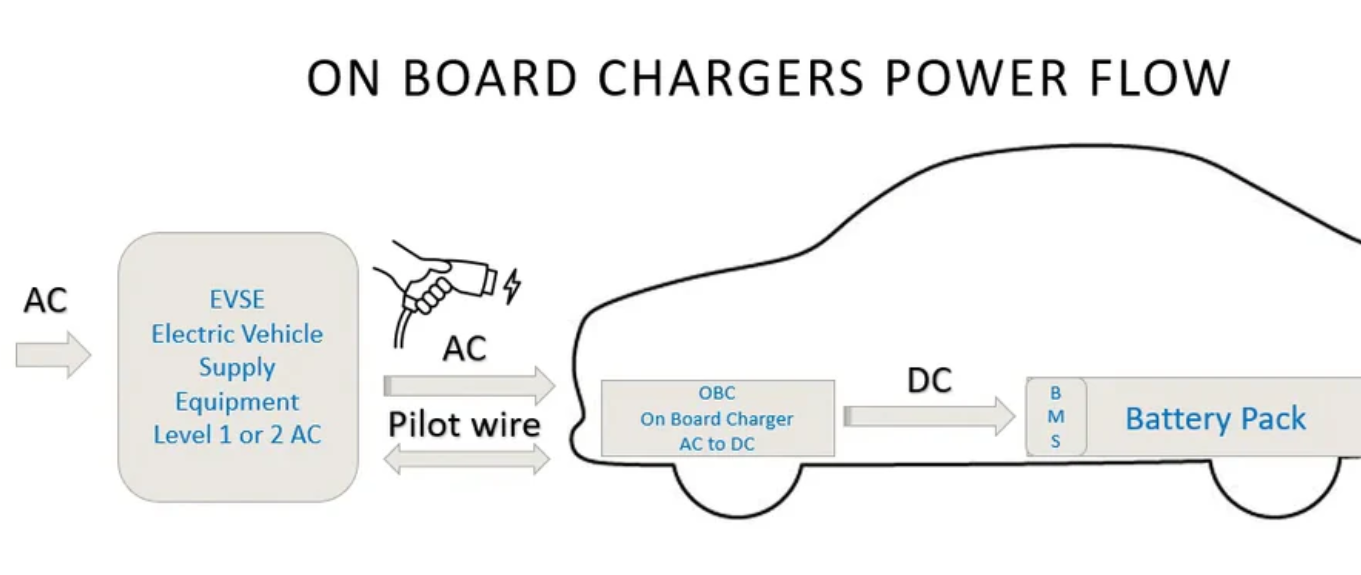

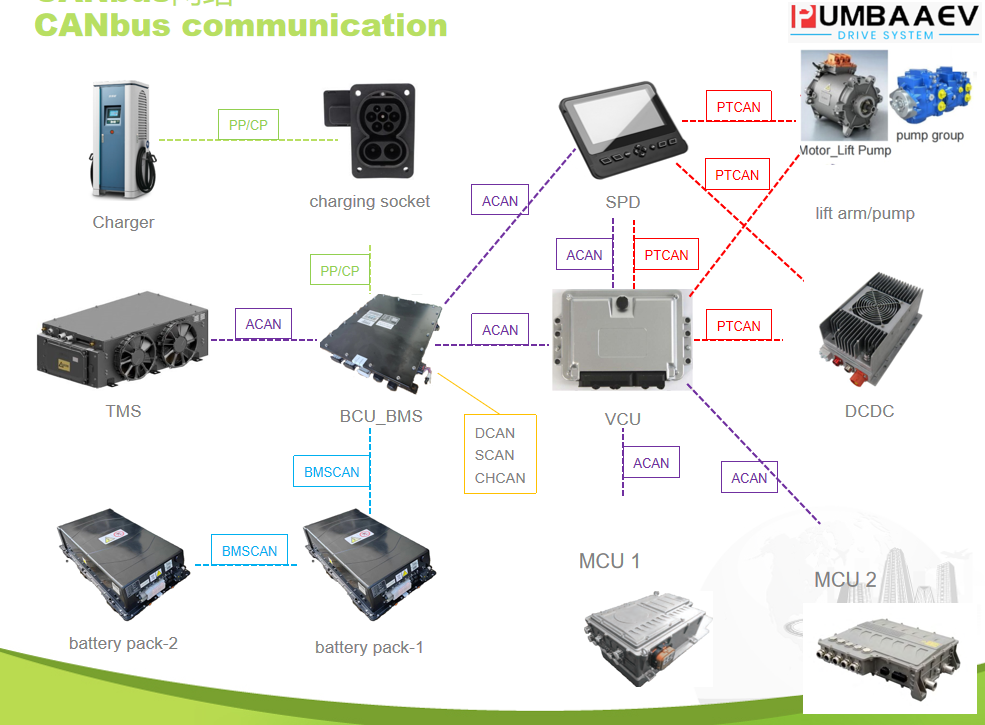

Technical scheme architecture diagram:

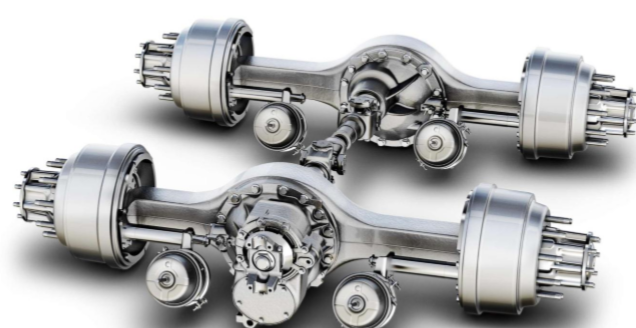

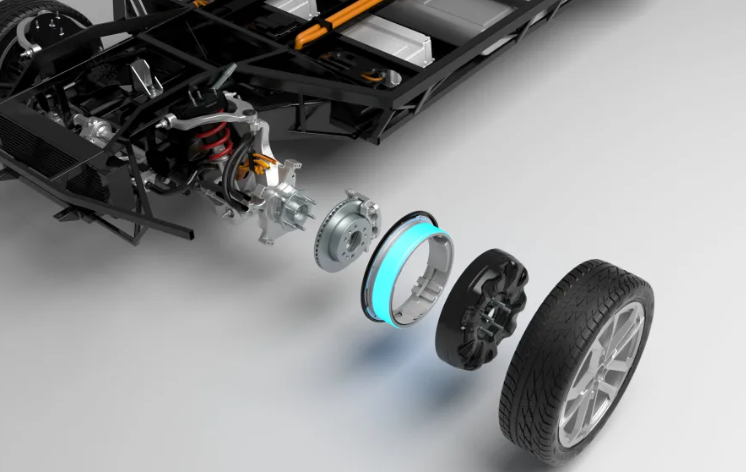

Its power system consists of 1 set of walking motor assembly + 1 set of oil pump motor assembly.

•Remove the original vehicle engine and hydraulic torque converter, diesel fuel tank, etc.;

•Remove the original engine related wiring harness and pipe line of the vehicle;

•Vehicle mapping, will layout with the key size to complete the mapping;

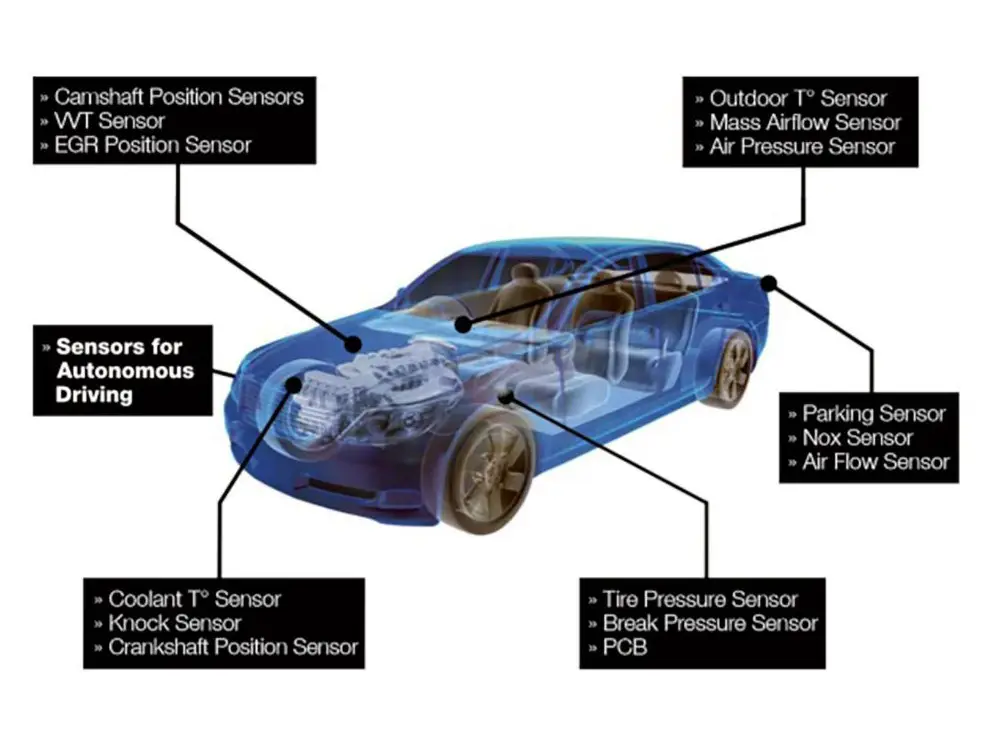

•Keep the controller of the hydraulic part of the original car, add the controller of the electrical part, the original hydraulic control logic remains unchanged;

•The electric controller is responsible for the control of the motor electric control, the battery and other components;

•Set up benches in China, realize logic debugging, and then package the tested parts and send them to foreign

countries for assembly and debugging on site;

Bench test drawing and production test drawing:

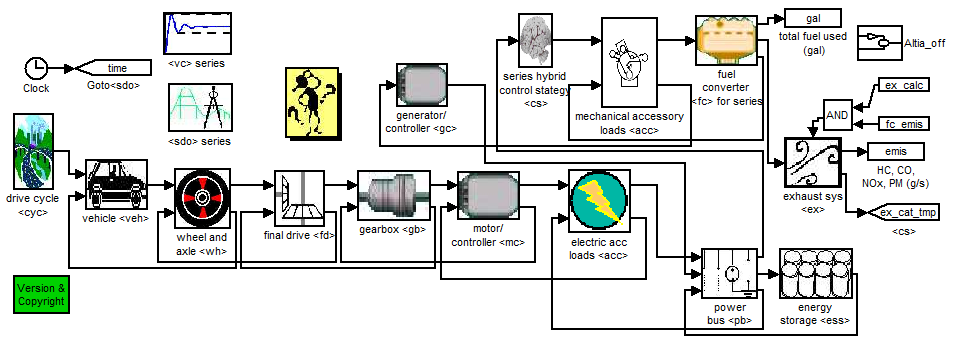

Vehicle simulation:

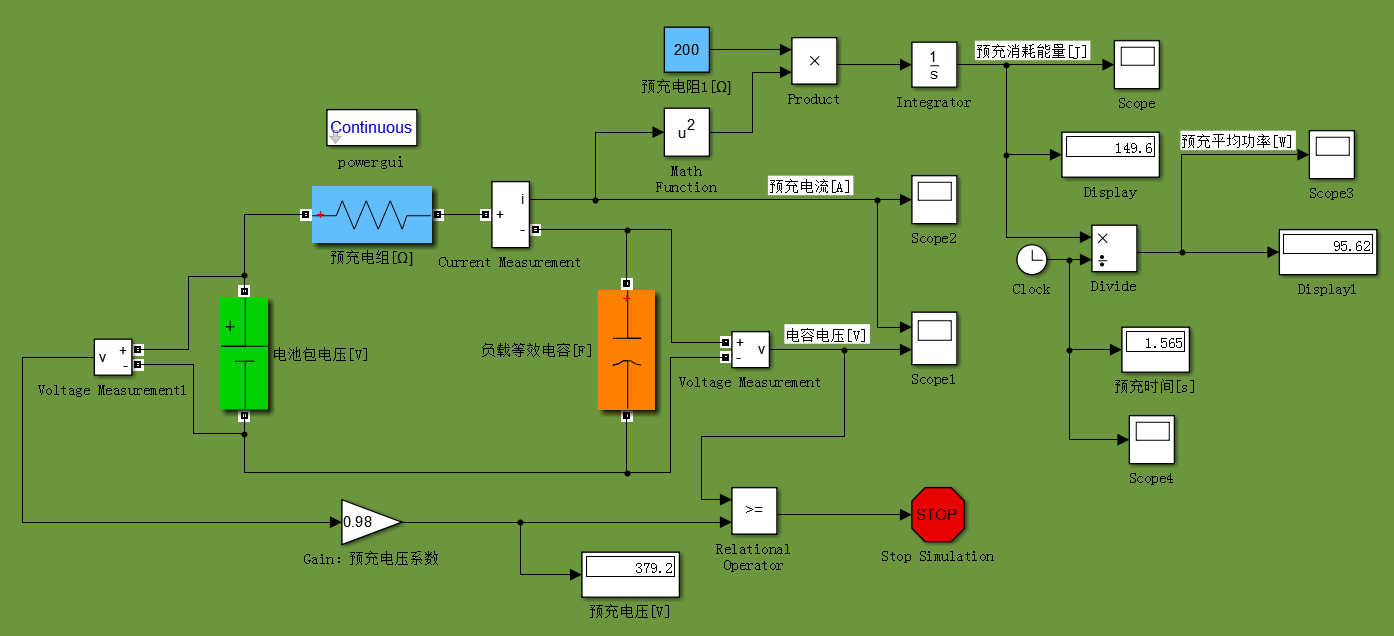

Electrical simulation:

The "oil to electricity" front crane has the following advantages:

1.Prolong the service life of the whole machine: the life of the electric system is more than 10 years, and the service life of the whole machine is extended when the structure of the whole machine is intact.

2.Operating costs are greatly reduced: after the completion of the front lifting "oil to electricity", the energy consumption cost of single container operation is greatly reduced. The whole operation will be electric, and the annual energy consumption and maintenance cost is expected to be reduced by 50% after the completion of the transformation.

3.To achieve zero emission of exhaust gas: front lifting "oil to electricity", with the use of "battery pack + motor" technology to replace the original internal combustion engine, reduce the energy consumption cost of equipment, and completely solve the problem of exhaust emissions.

4.Low noise: the noise generated by the motor is much less than that of the diesel engine, which can greatly reduce the noise pollution and improve the operating environment of the drivers.

5.Reduce the maintenance cost: the motor does not need frequent maintenance, and the maintenance cost is far lower than that of the diesel internal combustion engine.

6.The system structure is simple, the failure rate is reduced, convenient maintenance: the container front crane fault is mainly concentrated in the two large components of the engine and the gearbox. After the completion of the transformation can improve the stability of the equipment operation.

Field assembly picture:

Port officials said: " We will sustainably develop new container terminals with automation, electrification and efficient land use. Investing in electric front lifting is an important step in our journey, and this solution can also provide a reference for other lifting operations in the dock.”

In the next step, PUMBAA will continue to explore more intelligent and green solutions in energy conservation and emission reduction, ensure operation safety, improve production efficiency, "lead and demonstrate" in the construction of green and zero-carbon ports, and do research on "green, wisdom, modernization and standardization", so as to achieve high-quality development of the port and shipping industry.